Products

Mills

Our engineered-to-order mills help solve your advanced reduction, separation, and air classification challenges no matter your industry. Your customers will benefit from the quality and consistency of milling, and you will reap the rewards of satisfied customers.

Micronizer ® Jet Mill

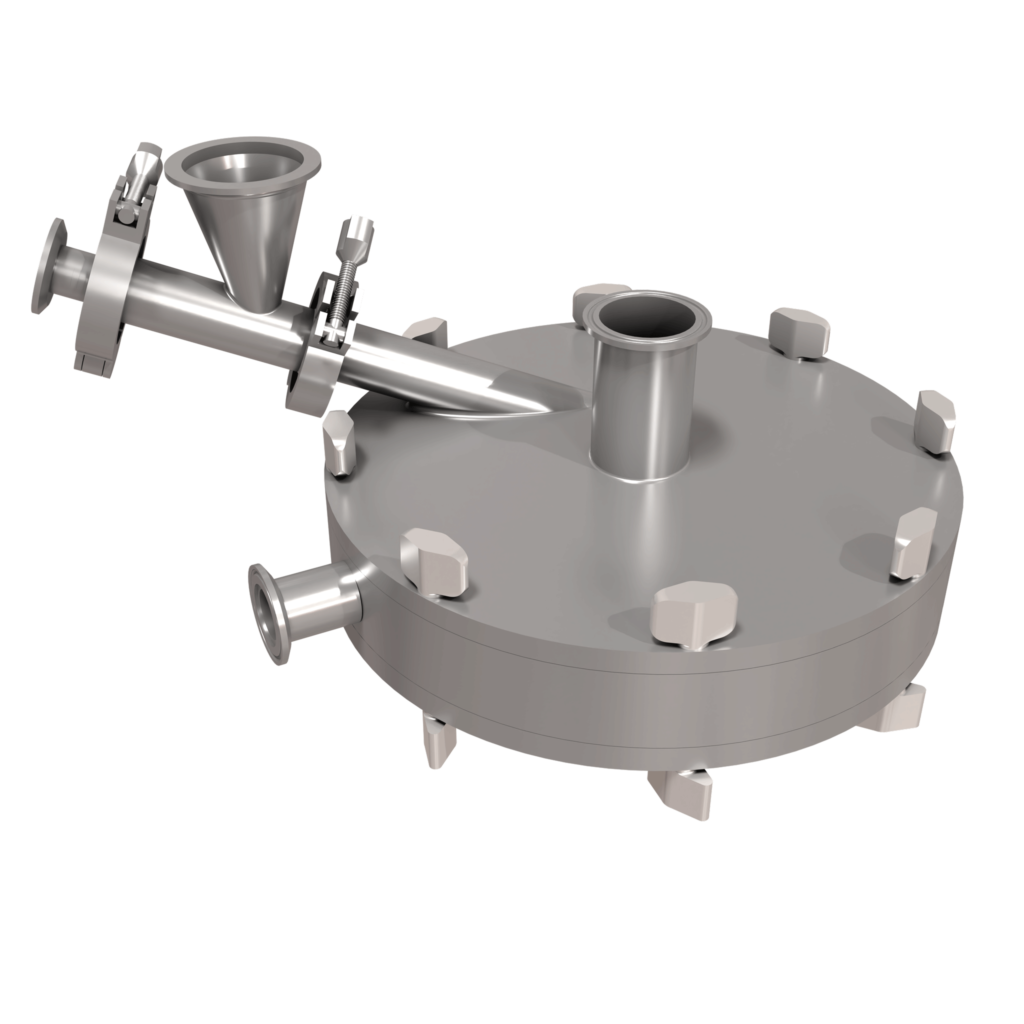

Sanitary Design Micronizer ®

Pharmaceutical Micronizer ®

Steam Micronizer ® Jet Mill

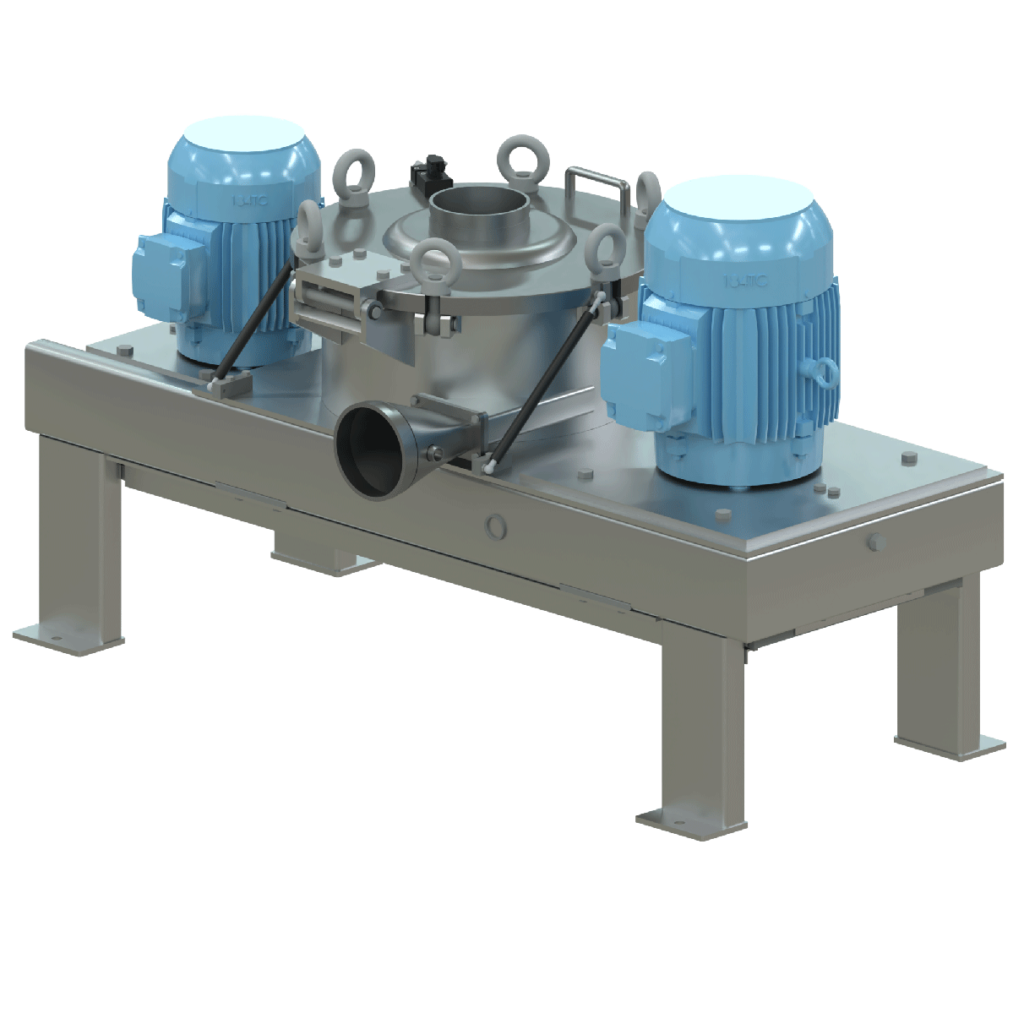

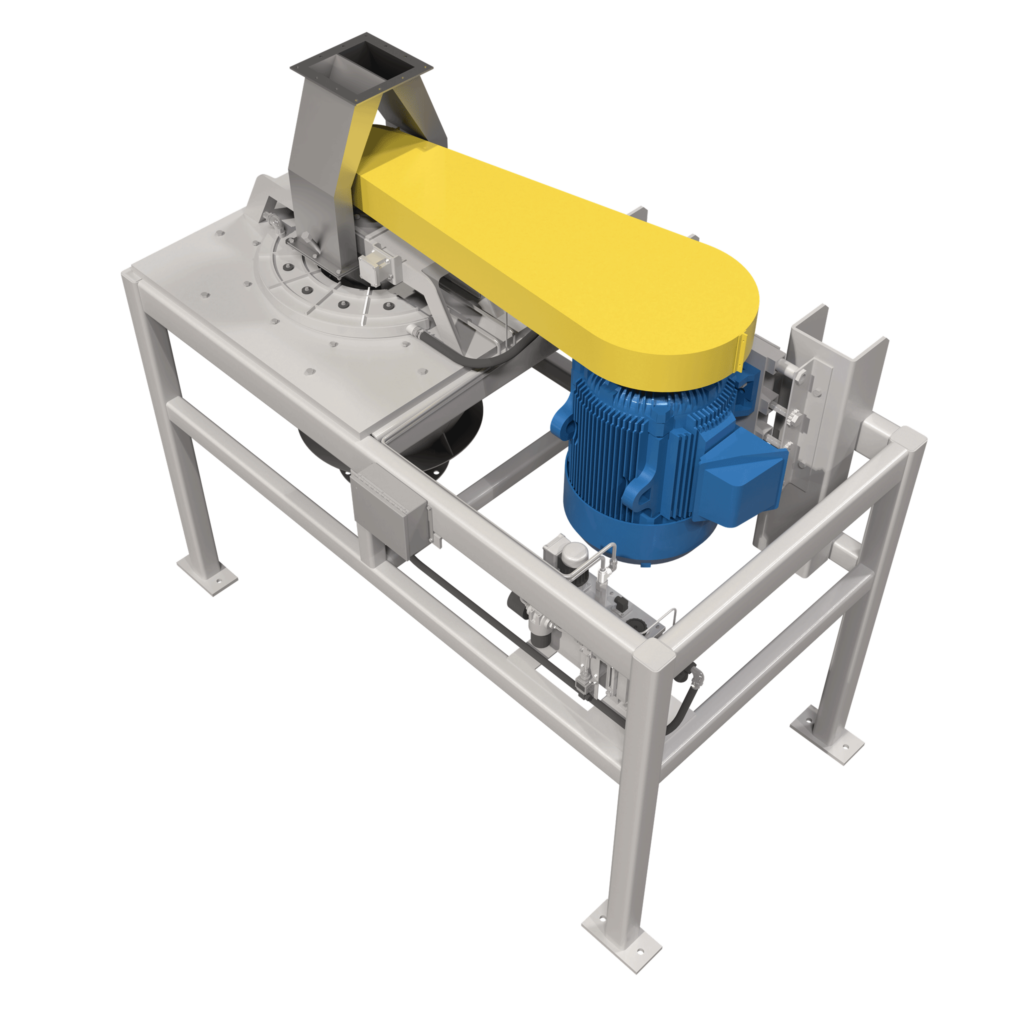

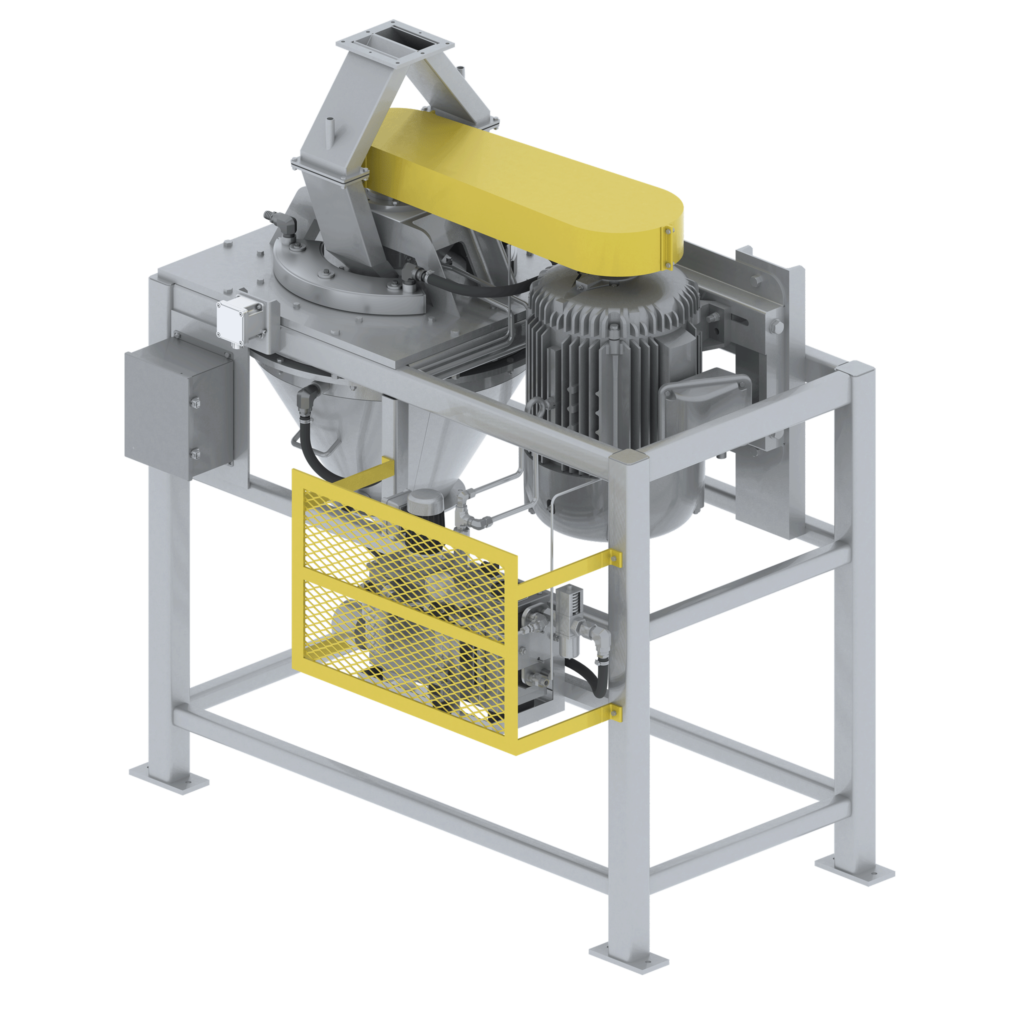

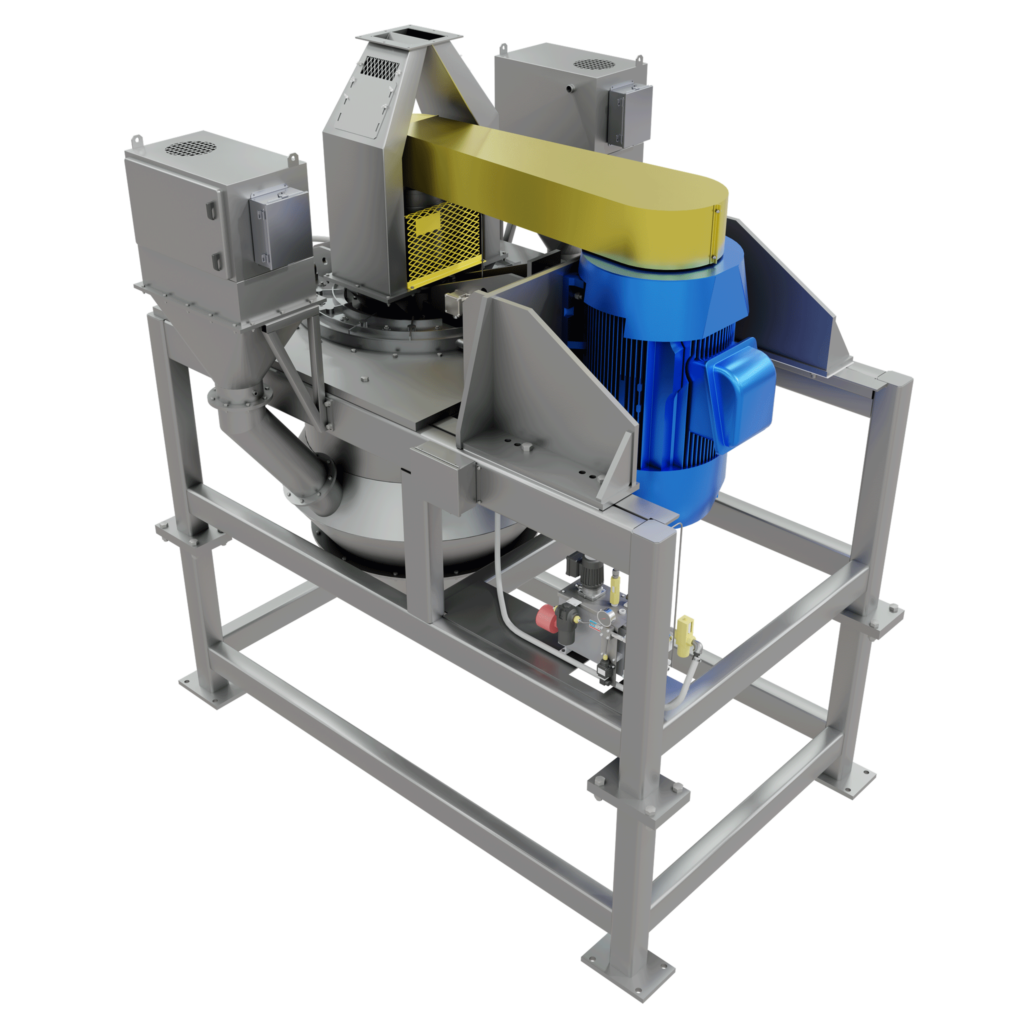

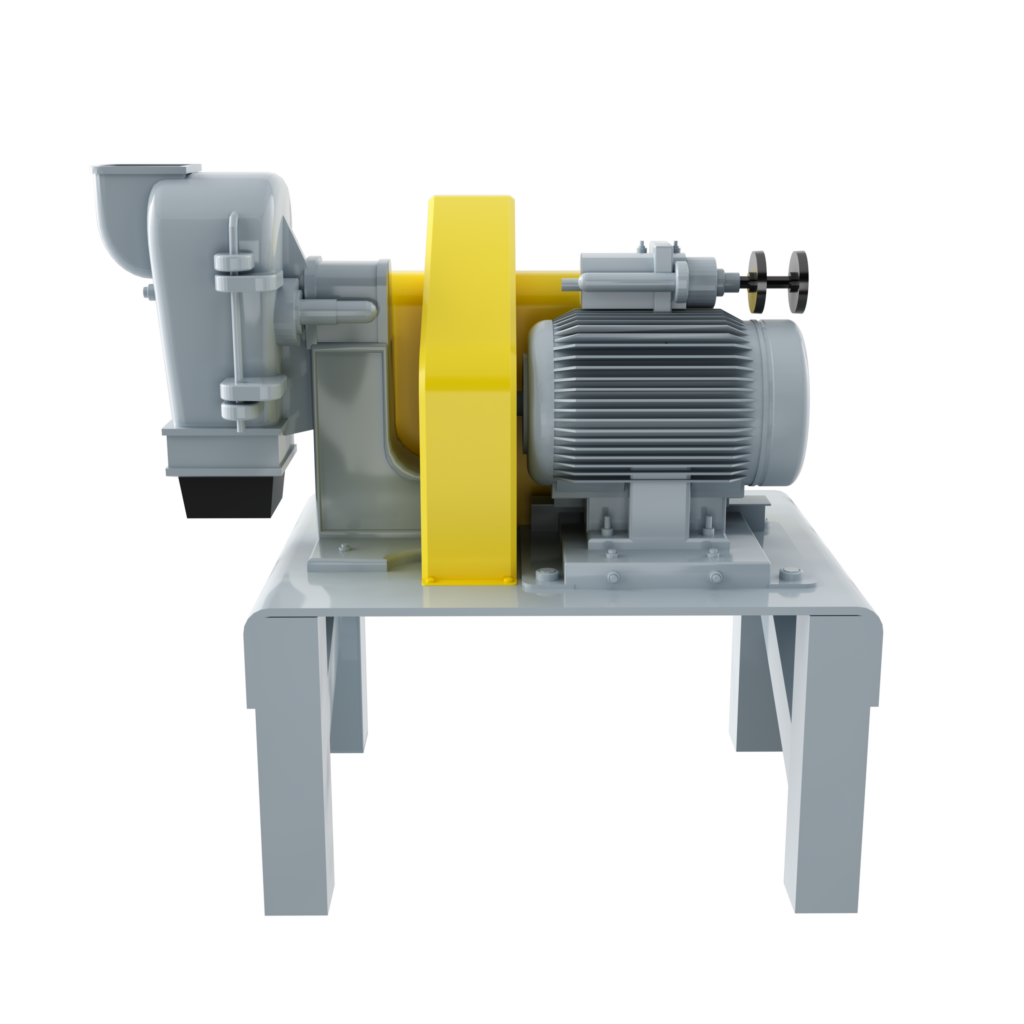

The FCM – Fine Classifier Mill

Combining both impact milling and air classification technologies in a single unit, the FCM Air Classifier is fast becoming the workhorse in particle size reduction across industries. The FCM’s integral classifier is capable of efficiently reducing powders down to 10 microns. And its flexibility of operation allows it to easily process a variety of product categories for a broad range of industries including pharmaceutical, food, chemical, mineral and others.

Infestroyer ®

The Infestroyer® is a centrifugal, pin-type impact mill that eliminates insect infestation in flour, bakery mixes, and other food products. The Infestroyer® eliminates insects with a 100% kill rate while preserving the particle size of the flour to maintain size and color.

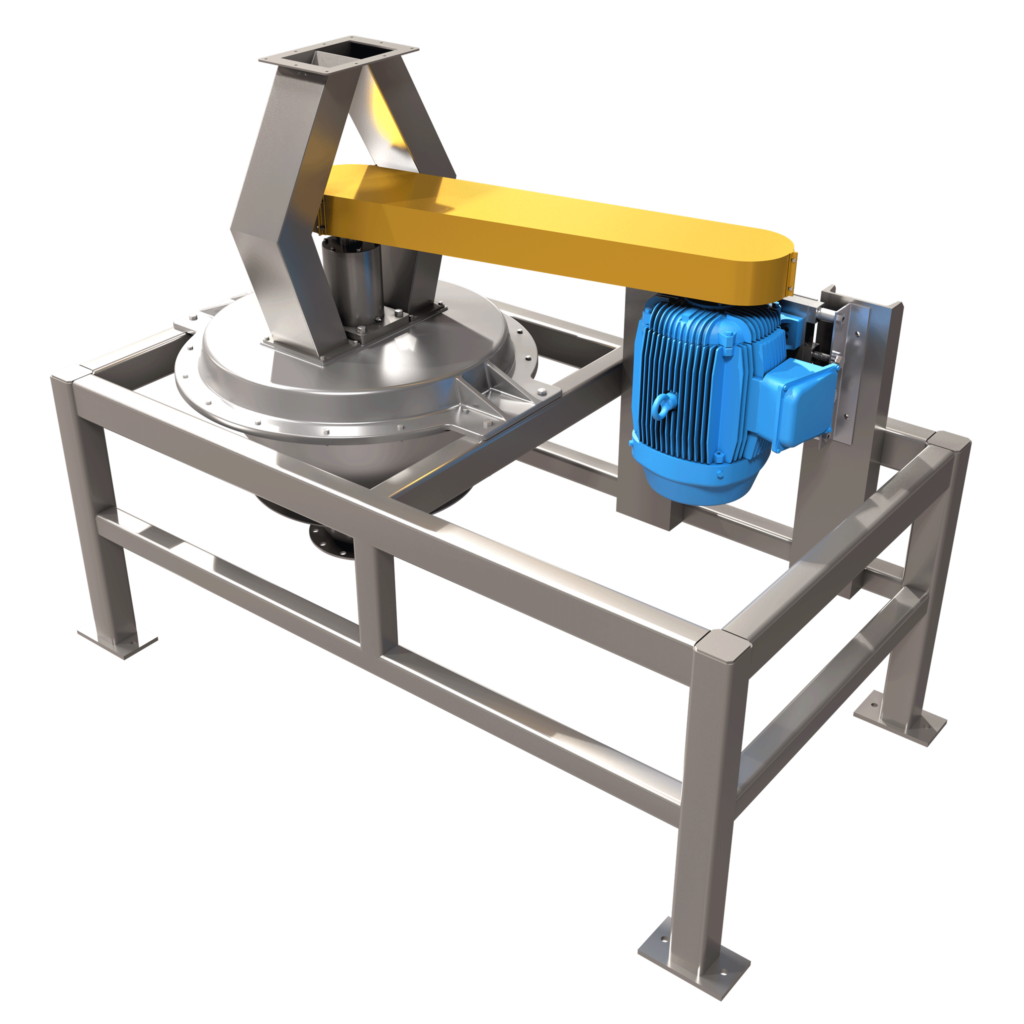

Simpactor ® Pin Mill

Simpactor ® FID Food Grade Mill

Simpactor ® FGT Series

Simpactor ® BVM Series

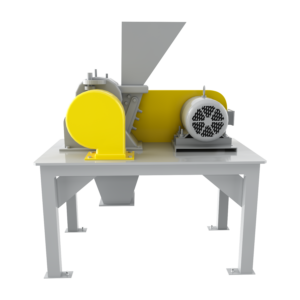

Sample Grinder

Our sample grinders are constructed from heavy-duty cast iron and are capable of producing material as fine as 100 mesh. Spring-loaded grinding discs assure uniform product sizes in applications such as chemicals, ceramics, minerals, and glass. The grinders are available in capacities from 50 lbs. to 800 lbs. per hour.

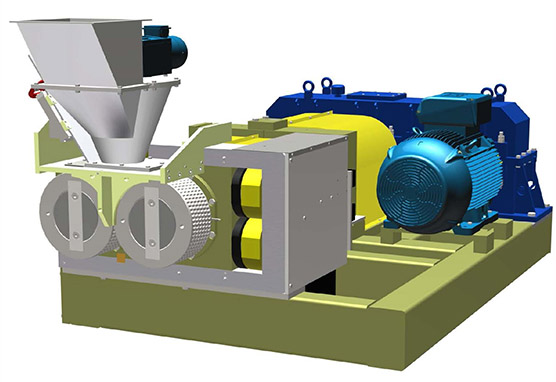

Hammermill

Sturtevant’s Hammermill provides excellent general size reduction for virtually any dry friable material. They are constructed from heavy-duty cast iron and are designed for the ultimate general size reduction of virtually any friable material. Materials are reduced to granular powder at a high rate through the use of swinging bar hammers. Product size is controlled be grates or screens. Available capacities are from 1/2 ton to 6 tons per hour. Suitable for a wide variety of applications including chemicals, minerals and limestone.

Solutions

Our Products

We are committed to being the premier global provider of material processing solutions for both conventional and leading-edge size reduction and air classification challenges around the world. Your success is our success and it all starts by delivering you the highest quality industrial-grade products.

Mills

Our engineered-to-order mills help solve your advanced dry material reduction, separation, and air classification challenges no matter your industry.

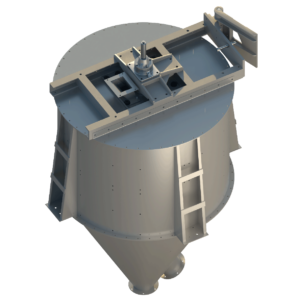

Crushers

These heavy duty machines ensure controlled size reduction for your customers’ toughest material processing jobs.

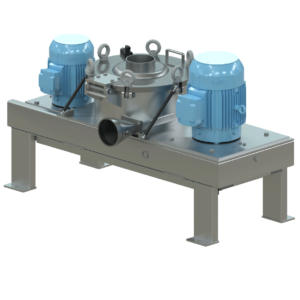

Air Classifiers

Our precision particle separation and air classification solutions deliver consistent, quality results every time.