SOLUTIONS

We are committed to helping you achieve success. From our engineered to order material size reduction and air classification solutions to our unwavering commitment to supporting you to solve conventional and complex challenges, no matter what industry you’re in.

SIZE REDUCTION AND AIR CLASSIFICATION SOLUTIONS

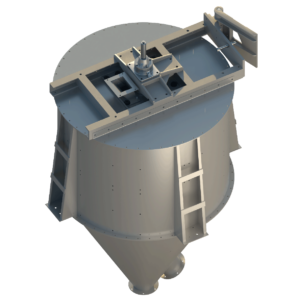

Mills

Our engineered to order mills help solve your advanced dry material reduction, separation, and air classification challenges no matter your industry. Your customers will benefit from the quality and consistency of milling and you will reap the rewards

of satisfied customers.

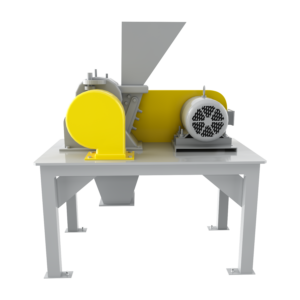

Crushers

These heavy duty machines ensure controlled size reduction for your customers’ toughest material processing jobs.

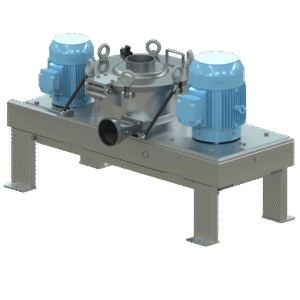

Air Classifiers

Our precision particle separation and air classification solutions are designed to separate your materials by size, delivering consistent, quality results every time.

SUPPORT AND SERVICES

Field

We offer consultation on operator training, quality control, economic viability, and more.

Remanufacturing

We rebuild equipment to OEM specs to ensure efficient operation.

Lab

At our fully equipped test facility our customers have the opportunity to learn, and test, onsite with highly qualified techs.

Parts

We have a wide range of replacement parts in stock all manufactured to OEM specifications.

Industries

Animal Nutrition

Proper pet nutrition is important to pet owners and as a pet food manufacturer, you want to deliver the highest quality products to meet customer demands. As a result, renderers and animal protein companies convert animal by-products into value added feed ingredients and create superior products at competitive prices. Our Whirlwind Air Classifier is the ideal solution to develop high-protein, low-ash feed ingredients that are highly digestible.

Pharmaceuticals

As a manufacturer of active pharmaceutical ingredients you are looking to reduce materials to a uniform particle size to increase the surface area which enhances dissolution and the bio availability of a drug. The rate of dissolution of a tablet or capsule is crucial and inadequacies in bioavailability can mean that the ingredients are ineffective or worse, potentially dangerous, leading to toxic overdose. While milling APIs and excipients, it is also important to avoid degradation and change in polymorphic form caused by excessive heat generation.

Stone, Sand, and Gravel Production

For most quarries, wet washing is an all too familiar method of removing 200 mesh fines from crushed stone screenings. Using water to separate fines is expensive and settling ponds require lots of land with added expenses. Our solution: air classifiers. Our Whirlwind air classifier provides the aggregate industry with a better way. It recycles nearly all of the working airflow and does not require a cyclone or baghouse to recover the fines.

Our Fly Ash air classifier controls the fineness of fly ash by air separating it at 200 325 mesh (75 45 microns), thereby reducing the LOI carbon content by 50% perfect for cement, filler for land reclamation, soil improvement, lightweight aggregates, and agricultural uses.

Cosmetics

Battery/Energy Storage

Chemicals, including lithium compounds, are air classified according to size or density. Air classification is the best solution for the job. But if the drying of lithium produces fines of 20% or greater pre classification is needed. Our solution: The SuperFine air classifier and the FCM Air Classifying Mill to successfully remove a portion of the lithium powder as a battery-grade. It can successfully remove 30% to 40% of the lithium powder as battery grade product prior to milling, leaving you only a fraction of lithium to be milled.

Food Grade Products

The Simpactor FID Mill, FCM Air Classifying Impact Mill, and SuperFine air classifier are the perfect solution for milling and separating dry powder food ingredients. Whether processing corn meal, soy proteins, sugar, nutraceuticals, or other food grade materials, our mills minimize material buildup and food contamination, allow for quick access to clean for minimal downtime, and offer maximum wear protection for lower maintenance hassles and costs.

Pigments

You care about color, particle size, refractive index, and delivery form. Processing pigments to fine particle sizes, with uniform surface area for consistent color uniformity, are vital to your success. Our Steam Micronizer is ideally suited for inorganic pigment powders like Titanium Dioxide (TiO2), and iron oxide with no moving parts it can reduce particle size or deagglomerate at rates up to 4 tons per hour.

Specialty Chemicals

Perfecting control of particle size is critical to the success of your operation, including processing materials used in agriculture, cosmetics, pharmaceuticals, cosmetics, and other excitable materials. Our air classification solutions provide the most effective means for separating a product from a feed stream, for dedusting, or when used in conjunction with grinding equipment for increasing productivity.