SERVICES

FIELD SERVICES

Sturtevant’s service department is available to assist you by telephone, e-mail or in the field. For the installation and start-up of new equipment and the maintenance of installed equipment, qualified serviceman can be onsite to provide a comprehensive field inspection to evaluate equipment’s condition and recommend adjustments and/or parts replacement.The service department can not only help you mechanically but also with processing and operational issues. Consultation with an application specialist is available to provide operator training, evaluate the best way to achieve fine particle sizes, validate product expectations and confirm economic viability.

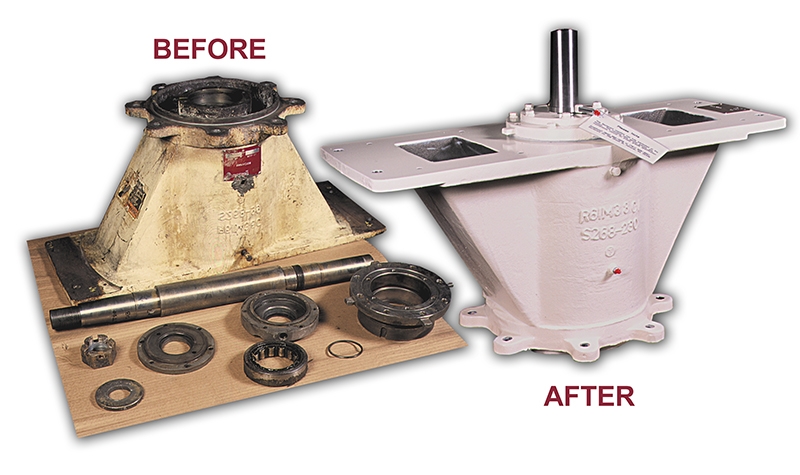

RECONDITIONING & REMANUFACTURING

Does your Sturtevant machine need repair or overhaul? We can rebuild your Sturtevant processing equipment to original factory specifications to ensure continued productive, efficient and safe operation. Our experienced technicians are trained to fit, mount and, when required, balance the parts to our machines with the expertise that has given Sturtevant the reputation of manufacturing well-built processing machinery since 1883.

We will provide the same commitment to quality and service by which we manufacture and deliver the original machines. Sturtevant continues to strive to improve the productivity, quality and value of our new process equipment and replacement parts. Our state-of-the-art balancing capabilities for high speed rotating assemblies provide the accuracy for vibration-free operation. Also, design improvements for retrofitting existing equipment have been made recently to several of our product lines to increase performance and dependability.

Sturtevant’s in-house service starts with an inspection of your equipment to determine the extent of wear and/or damage. A detailed cost quote will then be provided defining the condition of the machine and the new parts and modifications (when applicable) required. Upon your authorization, we will assemble the unit to original specifications and, in many cases, test the equipment before returning it to you.

REPLACEMENT PARTS

Do you need replacement parts for your Sturtevant equipment?

Replacement parts manufactured to OEM specifications are often in stock and are affordably priced. Please contact us to order your parts today and avoid costly downtime.

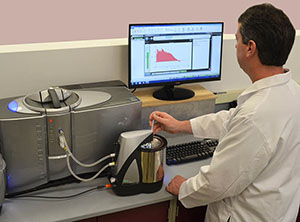

LABORATORY TESTING

Prior to scheduling a test, the following information is needed:

Completed MSDS (Material Safety Data Sheet)

Sturtevant Information Request Form

Approval from Sturtevant’s Safety Committee with a MATERIAL AUTHORIZATION NUMBER to ensure safe handling and processing of your material

Purchase order to cover the estimated cost of the test.

PROCEDURES:

Sample testing must be scheduled. To arrange for a mutually convenient time, contact our Sales Department at 1-800-992-0209. Please follow the proper sample testing and evaluation procedures outlined below. Do not send sample materials until contacting Sturtevant for a Material Authorization Number. Materials can’t be processed or tested without a current Material Safety Data Sheet (MSDS). Additional information may be required to ensure our employee’s safety.